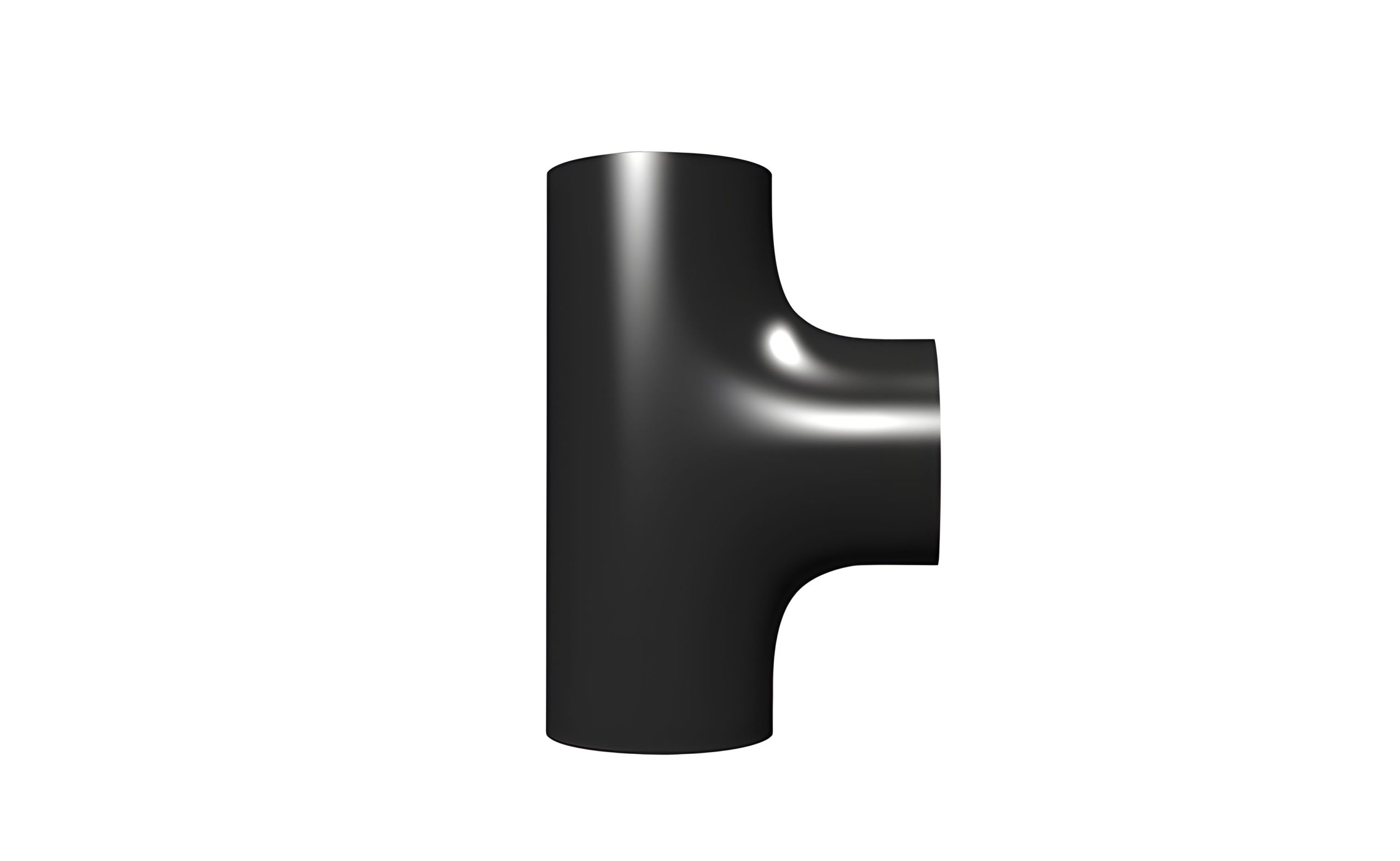

Tee fittings are connectors used at the branch point of a main pipeline in a piping system. They feature three ports (one inlet and two outlets, or two inlets and one outlet). They are categorized by pipe diameter as equal-diameter and reducing tees, and by branch configuration as T-shaped (straight tees) and Y-shaped (angled tees). They are available in over ten materials, including stainless steel, carbon steel, copper, and plastic, and are suitable for applications in the chemical, construction, petroleum, gas, and shipbuilding industries. Connection styles include butt welding, socket welding, and threaded connections, complying with standards such as GB, ASME, and DIN.

The manufacturing processes for these fittings are primarily hydraulic bulging and hot forming. Hydraulic bulging uses liquid pressure and mechanical extrusion and is suitable for mild steel and stainless steel pipes under DN400. Hot forming uses a heating-and-following radial compression process, enabling the production of larger diameter or thicker-walled tees and offering a wider range of material compatibility. Welded tees are further categorized into malleable cast iron, steel plate coiled tubing, and high-pressure forging. Integrally forged high-pressure tees have a maximum pressure resistance of 20.0 MPa.