1. Product Overview

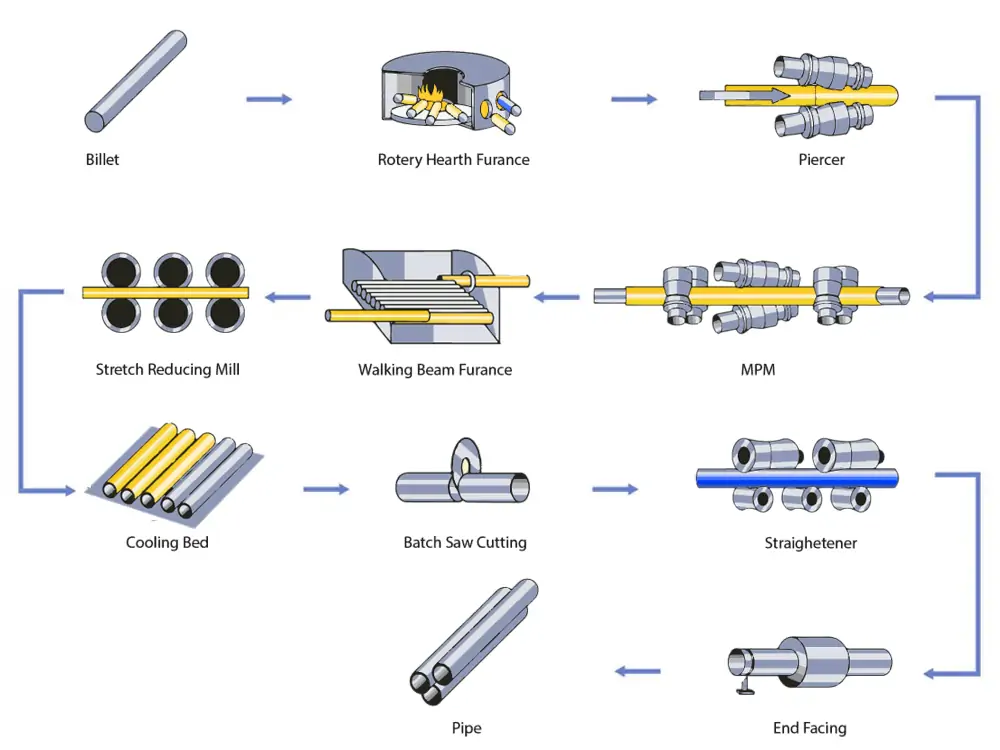

Seamless steel pipes are tubular products formed by piercing, drawing, rolling, or extrusion from a solid metal billet, resulting in a continuous, weld‐free structure. Thanks to their integral construction and reliability, these pipes exhibit excellent strength, pressure resistance, temperature tolerance, and corrosion resistance, making them vital materials across multiple industrial sectors.

2. Key Selling Points

| Feature | Description |

|---|---|

| High structural integrity | The absence of welds removes weak joints and enhances overall stability and leak resistance. |

| Excellent pressure and deformation resistance | Under high pressure or load, stress is evenly distributed, reducing local deformation risk. |

| Superior heat & corrosion resistance | In alloy or stainless steel versions, the pipe can maintain long-term stability in harsh environments. |

| Flexible processing & customization | Secondary operations like bending, expansion, drawing, polishing can adapt to complex project layouts. |

| High surface quality | Polishing, pickling, or cleaning treatments provide a smooth and consistent finish. |

| Long service life and low maintenance cost | Stable material properties and robust structure reduce replacement and maintenance frequency. |

3. Applications

-

Oil & Gas Industry

-

Chemical & Process Engineering

-

Power Generation & Thermal Plants

-

Boiler & Heat Exchanger Equipment

-

Mechanical Structural Components

-

Construction, Bridges & Support Frameworks

In these sectors, seamless pipes are commonly used in high-pressure conveyance, load-bearing supports, and corrosion-resistant piping systems.

4. Installation & Usage Recommendations

-

Material selection should consider the working environment (medium, temperature, pressure, corrosion).

-

For corrosive environments, adopt protective measures such as coating, internal lining, or inhibitors.

-

During installation, avoid excessive bending, stress concentration, or mechanical impact.

-

Perform periodic inspections using nondestructive testing, ultrasonic flaw detection, etc.

-

Reinforce sealing and corrosion protection at joints, flanges, welds.

5. Company Capabilities & Service Commitment

-

Equipped with modern production lines, automated equipment, testing instrumentations, and skilled technical teams;

-

Support customized manufacturing, sample trials, and after-sales technical support;

-

Implementation of strict quality control and outgoing inspections to ensure reliable delivery;

-

Rapid response to customer needs, flexible supply, and professional logistics support.