Definition & Manufacturing:

-

-

Butt-weld fittings primarily refer to pipe fittings connected via welding.

-

Manufacturing typically follows two paths:

-

Path 1: The fitting manufacturer uses welded pipes conforming to standards as raw material. These are formed into the required shapes (e.g., elbows, tees) through cold/hot forming processes (e.g., pushing, pressing, bending). This forming process itself does not include welding operations; the welding refers to the final connection to the piping system.

-

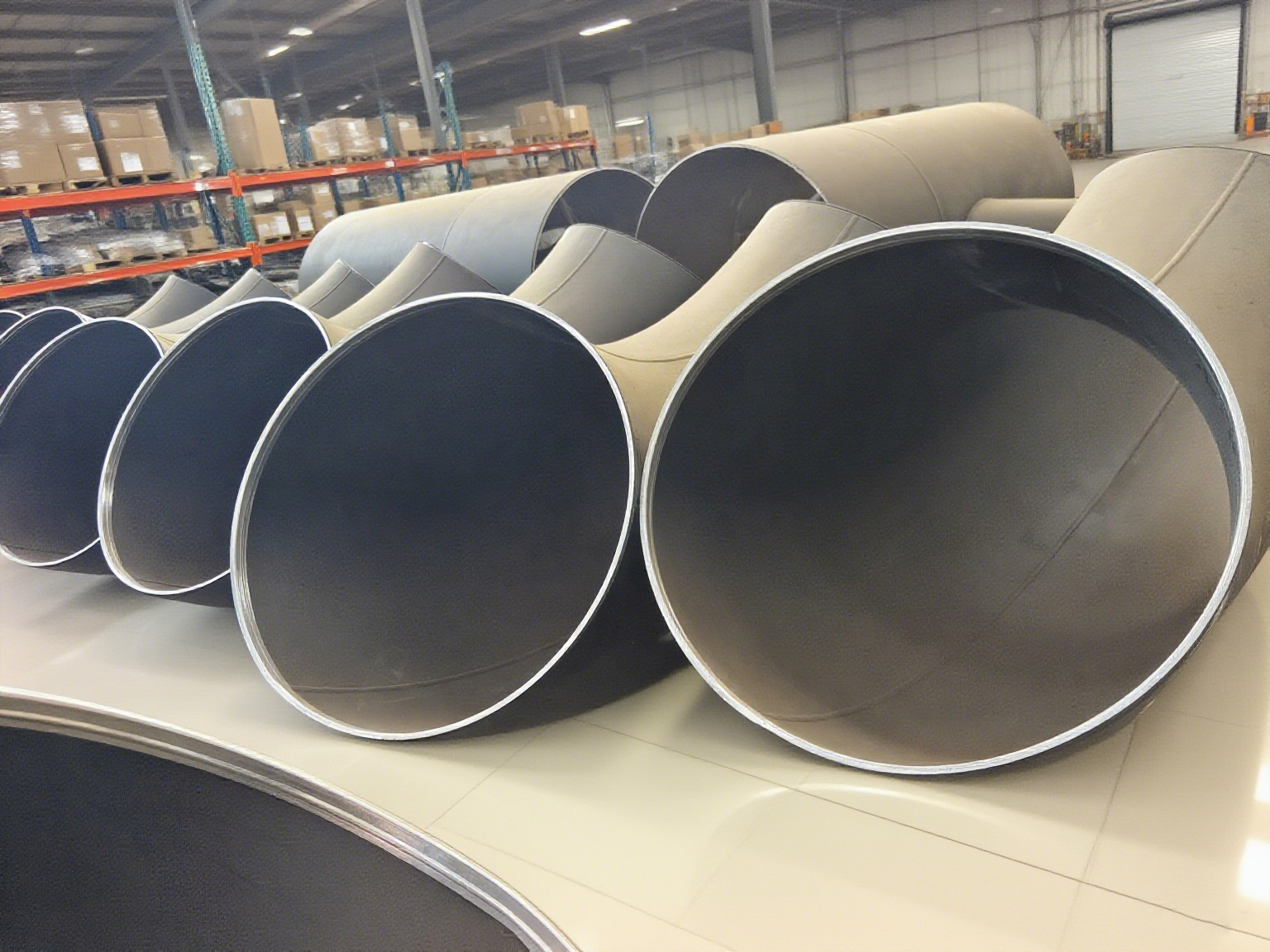

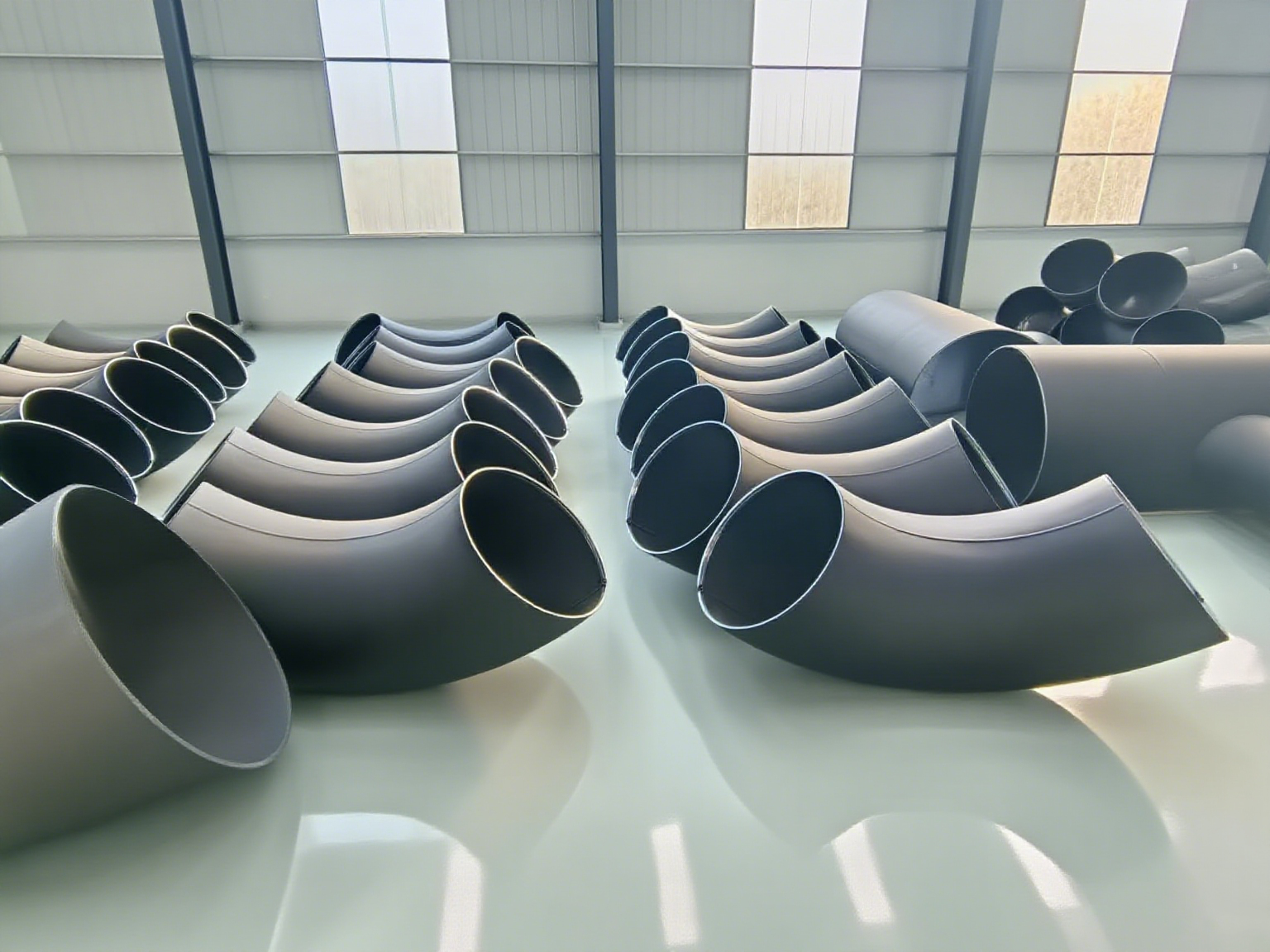

Path 2: The fitting manufacturer uses steel plates or strips. After cutting and forming (rolling, pressing), critical longitudinal or circumferential welds are performed in-house to create fitting blanks or finished products (e.g., large-diameter butt-weld elbows, reducers). This path inherently includes necessary welding operations.

-

-

Weld Neck Flanges are a prominent type of butt-weld flange, requiring the neck to be butt-welded to the pipe.

-

Heat Treatment:

-

Heat treatment requirements are dictated by the specific fitting product standard (e.g., GB/T, ASME, JIS) and material specification (e.g., ASTM, GB).

-

Heat treatment is NOT mandatory for all formed fittings.

-

Primary objectives of heat treatment:

-

Eliminate work hardening induced by the forming process.

-

Relieve residual stresses.

-

Improve or restore metallurgical properties altered by deformation.

-

Achieve mechanical properties (e.g., strength, toughness) or corrosion resistance mandated by standards.

-

Primary Types & Functions:

Elbow: Changes pipeline direction. Common angles: 45°, 90°, 180° (Return Bend).

-

-

Tee: Facilitates fluid branching or combining. Types: Equal Tee, Reducing Tee.

-

Reducer: Connects pipes of differing diameters. Types: Concentric Reducer, Eccentric Reducer.

-

Cap: Welded to pipe ends to provide sealed closure.

-

Cross: Connects four pipes at a single junction.

-