Petrobras/Brazi

KOC/Kuwait

Date: March 23, 2013 Recently, our company has successfully signed a significant supply contract with Kuwait Oil Company (KOC), under Contract No. 12050766. This milestone represents another solid step in expanding our presence in the Middle Eastern oil and gas market, particularly in Kuwait. Under the terms of the contract, our company will supply high-quality […]

KOC/Kuwait

Date: January 30, 2013Order No.: 42153End User: Kuwait Oil Company (KOC) Project Overview On January 30, 2013, our company successfully received the Order No. 42153 from Kuwait Oil Company (KOC), marking another significant milestone in our long-term cooperation with the Middle Eastern oil and gas sector. KOC, as one of the world’s leading state-owned petroleum […]

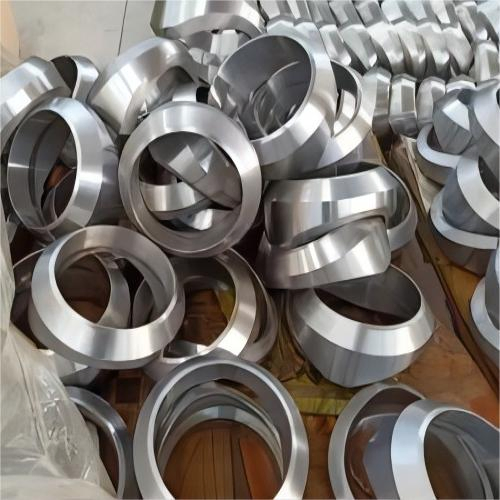

Sweepolet and Weldolet – High-Performance Pipe Connection Solutions

Sweepolet – Detailed Product Introduction Definition and Structure A Sweepolet is a type of “O-let” branch connection fitting (other common types include Weldolet, Sockolet, and Thredolet). It is a contoured, integrally reinforced, butt-weld branch connection used to create an outlet from a run pipe (header) to a branch pipe. Compared with a traditional Tee fitting, […]

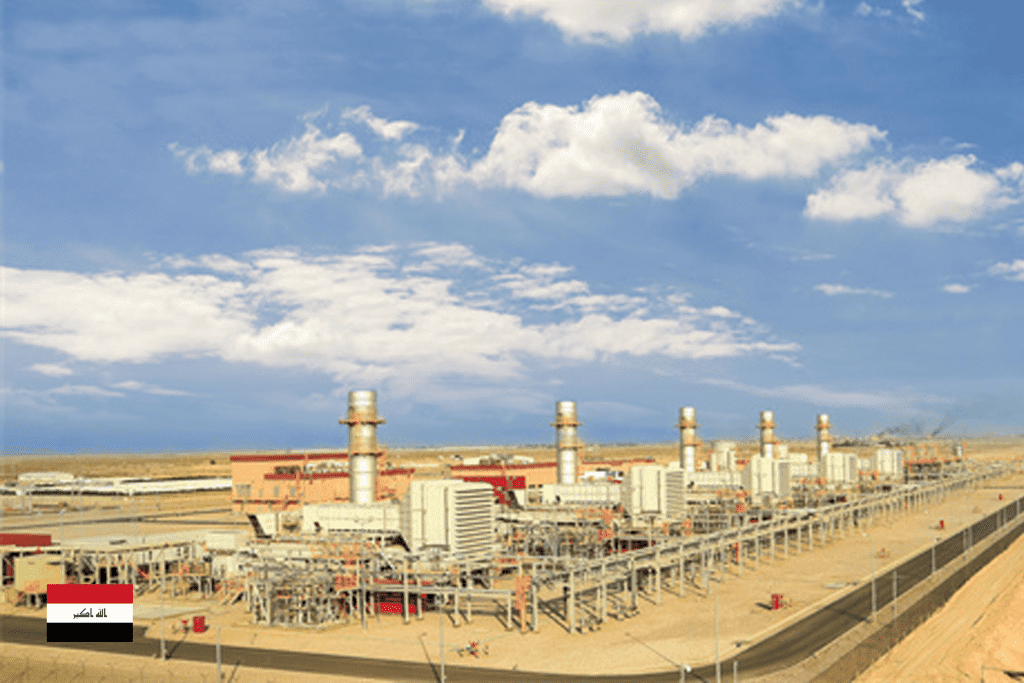

Our Company Successfully Wins Kurves Piping Order for SOUTH OIL COMPANY / BP in Basra, Iraq

Main Content 1. Project Overview Successfully won the Kurves Piping order (PO No. 0R105083) from SOUTH OIL COMPANY/BP in Iraq. The project, located in Basra, southern Iraq, is a joint development by BP and Southern Oil Company and aims to improve the production efficiency and transportation capacity of oil and gas fields. 2. Company Strength […]

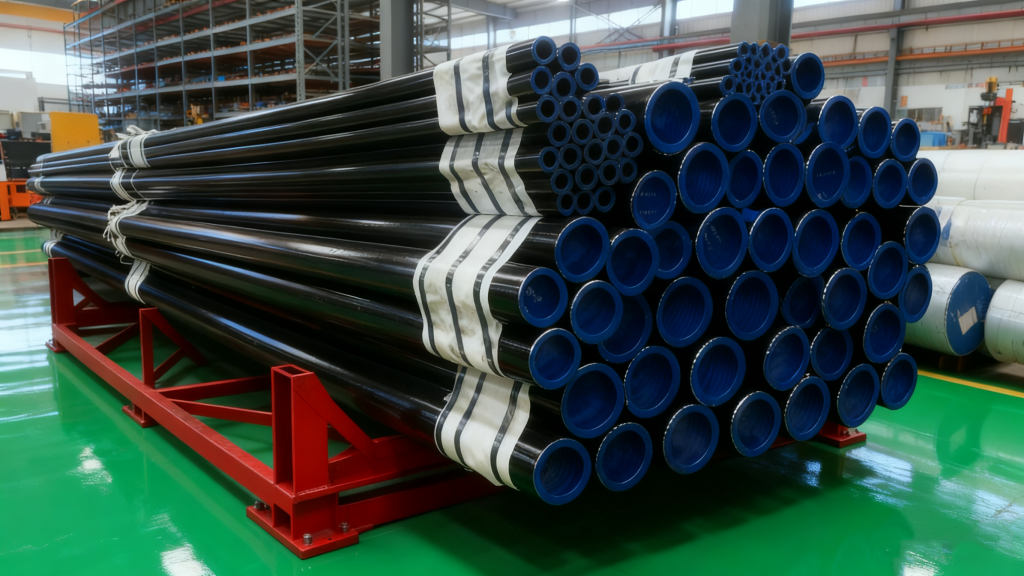

Carbon steel seamless pipe

Seamless carbon steel pipe is a type of steel pipe manufactured by piercing steel ingots or solid billets, followed by hot rolling, cold rolling, or cold drawing. It plays a crucial role in my country’s steel pipe industry. The production process includes billet heating, pressure piercing, rolling and extrusion, sizing and cooling, and flaw detection […]

seamless steel pipe

1. Product Overview Seamless steel pipes are tubular products formed by piercing, drawing, rolling, or extrusion from a solid metal billet, resulting in a continuous, weld‐free structure. Thanks to their integral construction and reliability, these pipes exhibit excellent strength, pressure resistance, temperature tolerance, and corrosion resistance, making them vital materials across multiple industrial sectors. 2. […]

British Petroleum (B.P) Rumaila Oil Field

English Version (Revised & Checked) 1. Project Overview and Environmental ChallengesThe Rumaila Oil Field, one of Iraq’s largest, operates under extremely harsh conditions, including ambient temperatures up to 50 °C, abrasive sandstorms, and highly corrosive soils and produced fluids (e.g. H₂S, CO₂, and chlorides). This project demands materials and components that deliver long-term integrity, minimal maintenance […]

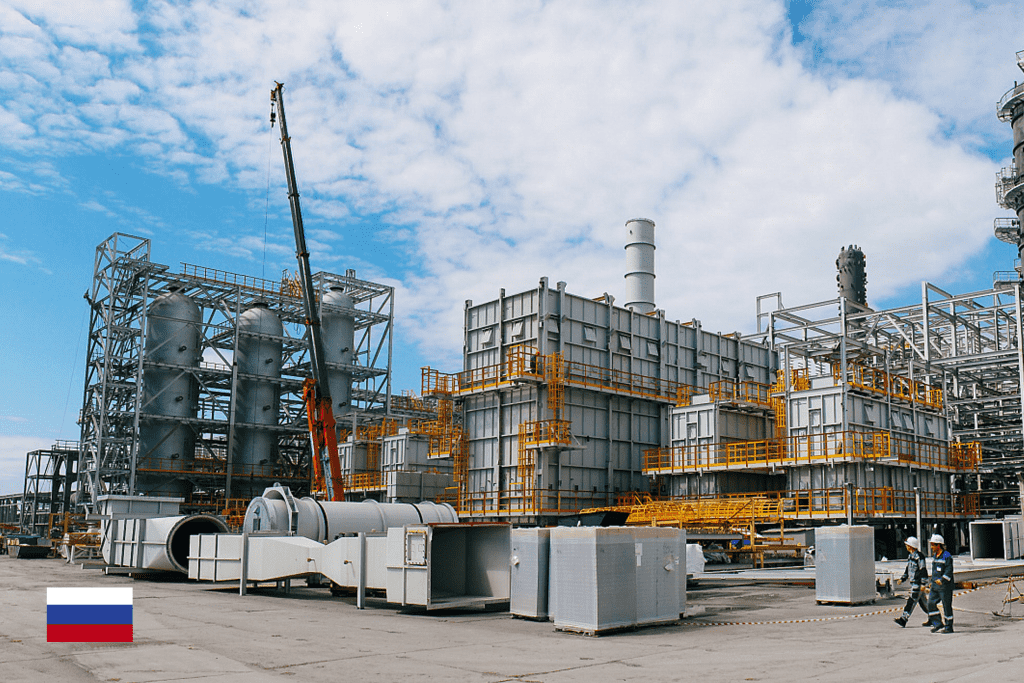

Afipka Oil Refinery, Russia

1. Project Background and Technical Requirements The Afipka Refinery Hydrocracking Complex is a pivotal component of Russia’s modernized refining infrastructure, engineered to process high‑sulfur crude oils and produce clean fuels that comply with Euro V standards. This project operates under extreme conditions — elevated temperatures (up to 550 °C), high pressures (up to 20 MPa), and highly corrosive […]